土木一 Benjamin Strodl

Conceptional Design Studio (CDS), a cornerstone course during the first semester, was undoubtedly one of the most inspiring and interesting courses so far. We were tasked with engineering a 1/20 scale model of a floating wind turbine, designed for the Xindian River near NTU.

We were provided with a realistic scenario: materials were limited, with each component assigned a unique unit cost. Moreover, the budget was constrained to 1200 NTD; however, the goal was to make it as cost-efficient as possible. Our tower would then undergo several stress tests, including a lateral force test, a floating stability test, and a mooring system test.

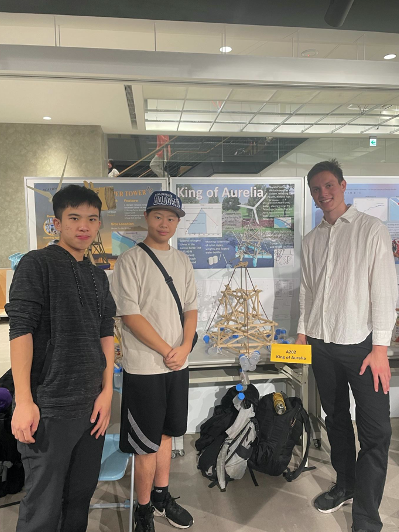

In the first two weeks, we brainstormed initial ideas for constructing the tower and visited the location for the first time. Based on our concepts, which we presented to the class, we formed groups of four. I teamed up with three excellent Taiwanese students: Yoyo, Ray, and Justin.

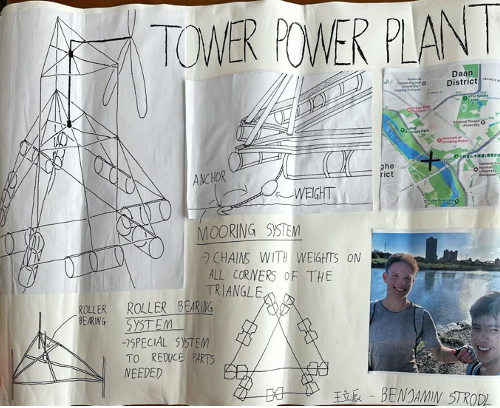

Our ideas after the first week

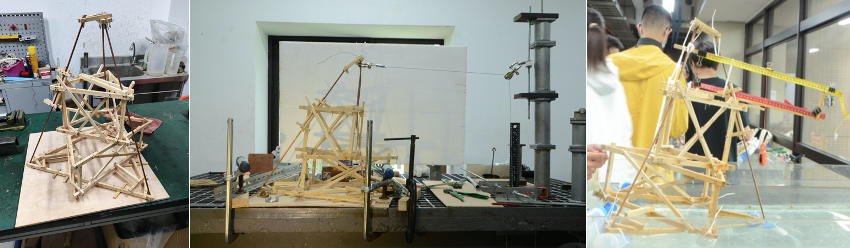

Our group had a unique design in mind: a predominantly triangular structure with a large base. Additionally, we became the first team in the course’s history to use copper tubes in the main structure. Initially, these were intended solely for the wind turbine and rotation mechanism, but we asked ourselves, “Why not use copper tubes elsewhere to enhance stability?” Despite their high cost, we concluded that the investment would be worthwhile.

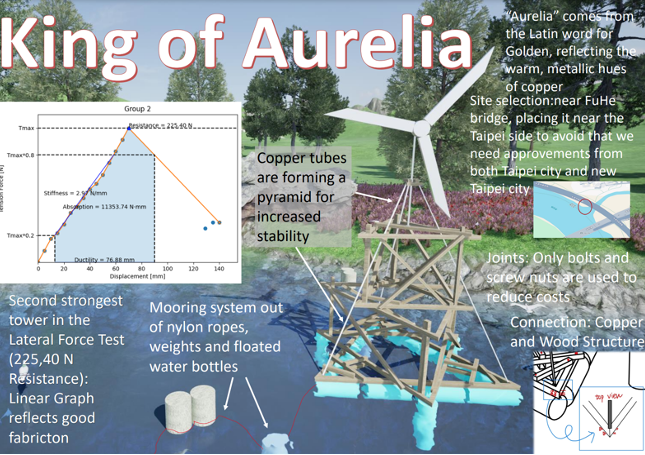

Specifically, our design included two triangular wooden floors with a copper tetrahedron, forming the tower’s top. Once we finalized our design concept, including joint details, we began constructing the “King of Aurelia,” the name of our tower. “Aurelia” comes from the Latin word for golden, reflecting the warm, metallic hues of copper. Nevertheless, our unique design posed several challenges. How would we connect the wood and copper in the structure? How could we cut costs, given the expense of copper tubes? In my opinion, our solutions were both neat and elegant.

For the joints, we used only bolts and screw nuts, whereas most other teams relied on costly copper sheets. In our project, bolts and screw nuts were free, which significantly reduced costs. They also improved stability by creating stiff joints. We managed to combine the copper tubes and wooden structure with pin connections made from screws. However, our design had a drawback: assembling the structure was time-consuming.

Our model during floating stability test and mooring system test

Ultimately, our efforts paid off. The “King of Aurelia” achieved the second-highest resistance in the lateral force test, with a linear rise in force absorption, indicating good fabrication quality. In this test, the tower’s top was pulled vertically while the base was fixed to the ground.

In the floating stability test, we also came in second, achieving the highest tilting angle due to our large base and low center of mass. For this test, a mass was applied to a horizontal wooden slat attached to the floating tower.

Finally, we scored the maximum points in the mooring system test. Our mooring system used only water bottles and nylon rope, while other groups incorporated additional components. This allowed us to keep costs relatively low, even with the copper tubes, spending 948 out of 1200 NTD of our budget.

Before the construction phase, we produced a digital model and plans for our tower, which greatly facilitated the building process. In the end, we created detailed engineering drawings so the tower could be reconstructed from scratch. My group members and I also designed a final poster to showcase and advertise our tower.

Our final poster

On December 20, we attended an award ceremony where we saw towers from other classes. One design, in which the entire tower was spinnable, stood out as particularly iconic—it was called “The Carousel.” In my class (Class A), the “Windiana Jones” team (composed of Hongda, CJ, Hsing, and Kun) won the award for best design. Prizes in various other categories were also awarded.

Team “Windiana Jones” with our Professor and TAs

CDS broadened my perspective on designing and constructing real-world structures, such as towers or other buildings. I learned to incorporate cost calculations into my ideas and take advantage of available resources—in our case, copper tubes. Additionally, I gained a greater appreciation for the time and complexity involved in constructing a design. Of course, I also acquired valuable knowledge about structural design, mooring, and flotation systems from Professors Capart and Ke, teaching assistants Diego and Isaac, and our experiments.